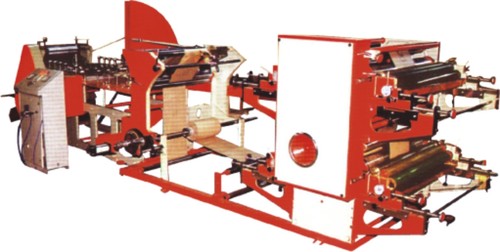

Paper bag making machine with printing

Paper bag making machine with printing Specification

- Product Type

- Paper Bag Making Machine with Printing

- General Use

- Manufacturing of paper bags with printing capability

- Efficiency

- High efficiency, up to 150-220 bags/minute

- Weight (kg)

- Approx. 2200-3500 kg

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Bag Type

- Shopping Bags, Grocery Bags, Food Bags, Carry Bags

- Computerized

- Yes

- Photoelectric Correction

- Available

- Film Length Counter

- Yes

- Bag Length

- 180 - 460 mm (adjustable)

- Power

- 6.5 - 9 kW

- Voltage

- 380V/220V, 50Hz/60Hz (customizable)

- Material

- Kraft paper, Art paper, Laminated paper

- Dimension (L*W*H)

- 5200 x 1800 x 2000 mm

- Feature

- Inline flexo printing; automatic counting; bag length control

- Color

- Industrial Grey/Blue (customized on request)

- Cutting Type

- Automatic precision rotary cutting

- After-Sales Support

- Spare parts and technical support provided

- Air Pressure Requirement

- 0.5MPa

- Paper Thickness Range

- 30-120 gsm

- Noise Level

- <75 dB

- Roll Feeding Diameter

- 1000 mm max

- Max. Bag Gusset

- 0-180 mm

- Production Speed

- 150-220 bags per minute

- Control System

- PLC touch screen interface

- Printing Color Option

- Up to 2/4 color inline flexo printing

- Main Motor

- Servo motor drive

- Max. Bag Width

- 80 - 450 mm (adjustable)

- Installation Service

- Available on request

Paper bag making machine with printing Trade Information

- Minimum Order Quantity

- 1 Piece

- Sample Available

- Yes

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015 CE CERTIFIED

About Paper bag making machine with printing

Introducing the Latest paper bag making machine with printing, the Prime choice for businesses seeking sizzling efficiency and unrivaled production capacity. Offering up to 2/4 color inline flexo printing, this automatic Ace is designed for adjustable paper thickness (30-120 gsm) and bag dimensions. With a rapid production speed of 150-220 bags per minute, precision rotary cutting and a PLC touch screen interface, it delivers standout quality. Built with a servo motor drive and smart air pressure control, it ensures minimal noise, seamless operation, and enhanced reliability. Ideal for shopping, grocery, and food bags, this machine is perfect for exporters, manufacturers, and suppliers.

Applications and Key Features

The Paper bag making machine with printing is widely used for producing shopping bags, grocery bags, food bags, and carry bags. Key special features include up to 2/4 color inline flexo printing, automatic counting, adjustable bag length control, and a servo motor drive system. Other notable elements are the PLC touch screen control, photoelectric correction, and compatibility with kraft, art, and laminated paper. Its high adaptability and efficient operation make it ace equipment for commercial bag manufacturing.

Shipment, Sample, and Payment Policies

Transport services ensure timely arrival with stock ready for swift dispatch. Sample policies are tailored to meet client needs, supporting evaluation before final purchase. Payment terms are flexible, accommodating various arrangements for exporters, manufacturers, and wholesalers. Supply ability guarantees a consistent delivery rate, minimizing delays and ensuring smooth business operations. Installation service is available on request, while after-sales support and spare parts are always at hand for customer peace of mind.

Applications and Key Features

The Paper bag making machine with printing is widely used for producing shopping bags, grocery bags, food bags, and carry bags. Key special features include up to 2/4 color inline flexo printing, automatic counting, adjustable bag length control, and a servo motor drive system. Other notable elements are the PLC touch screen control, photoelectric correction, and compatibility with kraft, art, and laminated paper. Its high adaptability and efficient operation make it ace equipment for commercial bag manufacturing.

Shipment, Sample, and Payment Policies

Transport services ensure timely arrival with stock ready for swift dispatch. Sample policies are tailored to meet client needs, supporting evaluation before final purchase. Payment terms are flexible, accommodating various arrangements for exporters, manufacturers, and wholesalers. Supply ability guarantees a consistent delivery rate, minimizing delays and ensuring smooth business operations. Installation service is available on request, while after-sales support and spare parts are always at hand for customer peace of mind.

FAQs of Paper bag making machine with printing:

Q: How does the inline flexo printing feature benefit the paper bag making process?

A: The inline flexo printing feature allows for direct, high-quality color prints on bags as they are produced, increasing efficiency and delivering professional results without extra steps.Q: What types of paper materials can this machine process for bag manufacturing?

A: This machine works seamlessly with kraft paper, art paper, and laminated paper, making it versatile for various packaging needs.Q: When can installation service be arranged for this machine?

A: Installation service is available on request and will be scheduled upon order confirmation to ensure proper setup and training at your facility.Q: Where can the paper bag making machine with printing be supplied from in India?

A: The machine is supplied directly from the manufacturer, exporter, supplier, and wholesaler based in India, ensuring prompt availability and support.Q: What is the process for after-sales support and spare parts provision?

A: After-sales support includes technical guidance, troubleshooting assistance, and a reliable supply of spare parts to ensure uninterrupted machine operation.Q: How is production speed managed and what is the prime output capability?

A: Production speed is controlled via a PLC touch screen interface and servo motor drive, allowing for adjustments to output between 150-220 bags per minute as required for your business.Q: What usage options are enabled by the adjustable bag sizes and length features?

A: The adjustable bag width, gusset, and length options enable the machine to produce a variety of bag types for shopping, groceries, and food packaging, tailored to specific needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paper Bag Making Machine Category

Fully Automatic Paper Bag Making Machine

Price 550000 INR / Piece

Minimum Order Quantity : 1 Piece

Bag Type : Paper Bag

Drive Type : Electric

Automatic Grade : Fully Automatic

Warranty : 1 Year

Food Paper Bag Making Machine

Price 550000 INR / Piece

Minimum Order Quantity : 1 Piece

Bag Type : Carry Bag

Drive Type : Electric

Automatic Grade : Automatic

Warranty : 1 Year

Hi-Speed Paper Bag Making Machine

Price 550000 INR / Piece

Minimum Order Quantity : 1 Piece

Bag Type : Paper Bag

Drive Type : Electric

Automatic Grade : Automatic

Warranty : 1 Year

Paper Shopping Bag Making Machine

Price 550000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Bag Type : Shopping Bag

Drive Type : Electric

Automatic Grade : Automatic

Send Inquiry

Send Inquiry Send SMS

Send SMS